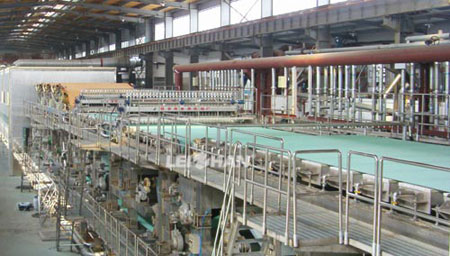

Paper Machine Making Line

Different kinds paper making maybe need different types paper machine, but almost paper making machines are made of the four sections: the wet end, the press section, the dryer section and the calendar section.

Paper Making Machine Process

The Wet End: The wet end is where the wood pulp in its slurry form, which is pulp mixed with water, is delivered to the paper making machine. The pulp is usually directly brought the wet end.

The Press Section: The press section is for removing the water in the pulp, it works by pressing the rolls against each other. Some of the pressed water is carried out by press felt, The rest is removed by suction with a vacuum chamber. In addition to helping remove more water, the press section smooth the paper pulp.

The Dryer Section: In the dryer section, there still have some water in the pulp, so the dryer section is to reduce the water content with steam-heated rollers.

The Calendar Section: The calendar section benefits to further smooth paper and creates a more uniform thickness. The pressure placed on the paper determines the finished paper gloss.

Contact us

Zhengzhou Leizhan Technology Paper Machinery Company

Office Add: Hetun Industrial Area, Dawei Town, Xinmi City, Henan Province, China

Email: leizhanpulper@gmail.com

Tel: +86 371 55129198

Fax: +86 371 86138029