Solution

Paper Mill Pulper Grapple

We produce grapple, which are used to grab various impurities in the pulper and improve the efficiency of pulping work. Paper mills have more needs and provide matching pulpers and other pulping equipment.

Read more

Energy Saving Beating Pulp Double Disc Refiner

The refiner is a necessary equipment in the pulp production process to improve the beating degree. RF series double-disk refiner is designed to retain fibers to a greater extent, such as the advancing and retreating knife device and the knife disc.

Read more

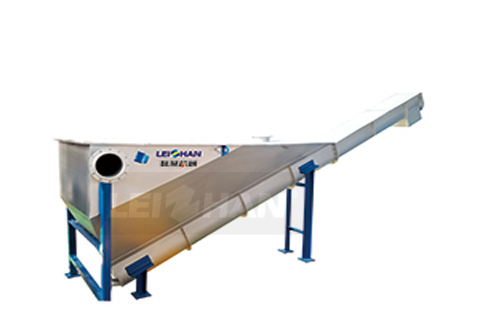

7t/d Slag Lifting Machine

Leizhan has a dedicated technical department to provide customers with supporting equipment and products. If you need to equip a new slag lifting machine, we can provide professional technical guidance and product details.

Read more

Paper Recycling Plant Full Line Machinery

Leizhan is a professional manufacturer of waste paper recycling equipment, providing a variety of equipment models to meet customer needs. Raw materials can be waste paper, pulp board, commercial wood pulp, etc.

Read more

Small Paper Pulp Egg Tray Machine

Egg trays generally refer to packaging tools used to hold eggs, duck eggs, etc., and those made of pulp are also called pulp egg trays.

Read more

Bale Opening Machine

Bale opening machine is the main product of Leizhan, and it is the best choice for processing waste paper and unpacking. Leizhan provides a variety of waste paper recycling equipment and the entire pulping production line for paper mills.

Read morePaper Mill Pulp Blender

Paper pulp blender, also called propeller, agitator. We produce pulp tank blenders for paper mills, different models, high-quality, advanced pulp blenders for paper mills with adjustable blades.

Read more

Pulp Inflow Pressure Screen

Inflow pressure screen is our flagship product, which is the most advanced pulp screening equipment in the world. Inflow pressure screen is used for pulp fine screening before the headbox, with less faults in continuous operation and low maintenance cost.

Read morePage Links: First PagePrevious7475767778798081828384NextLast Page