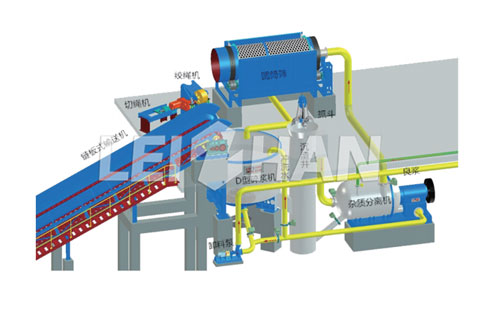

D Type Low Consistency Continuous Pulping System

In the paper making industry, the effective crushing of waste paper raw materials that contain high impurities and are difficult to crush, such as LOCC and AOCC, has always been a challenging process. To address this problem, Leizhan’s D-type continuous crushing system It can meet your needs, improve crushing efficiency and improve pulping capacity.

D Type Low Consistency Continuous Pulping System Equipment

D type hydrapulper: Through cutting, tearing and stirring, waste paper raw materials are quickly broken down into pulp while maintaining the continuity of the breaking process.

Trash well: Collect and remove heavy residue in the pulper to keep the crushing environment clean.

Hydrapurger: Regularly remove debris from the pulper to ensure stable operation of the system.

Drum screen: Responsible for dehydrating and removing the residue after cleaning by the impurity separator to ensure the quality of the pulp.

Ragger: Specially used to remove large and entangled debris in the pulper and improve the efficiency of continuous crushing.

Rope cutter: Cut off the entangled material removed by the rope cutter to facilitate transportation and handling.

Grapple:Remove heavy residue from the trash well and keep the disintegration environment clean and stable.

Leizhan has specialized in manufacturing paper making machinery for more than 40 years and has been committed to providing efficient paper making solutions. If you want to know more about the D type low consistency continuous pulping system, please contact us for details. Email:paperproductmachine@gmail.com