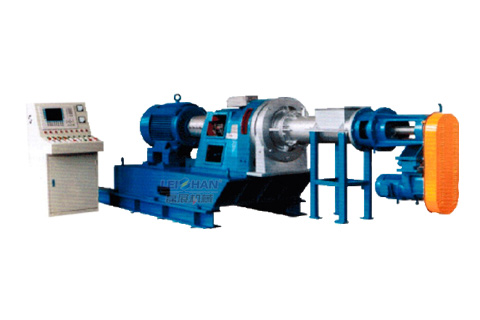

Heat Dispersion for Recycled Fiber System

Heat Dispersion is used in recovered fiber systems for dispersing unwanted impurities like stickies, grease, wax, plastic, rubber and ink particles to a size not affects downstream equipments processing.

Disperging can remove and reduce residual ink particles in paper pulp, which is good for efficient deinking in Flotation deinking cells.

In recovered fiber systems for brown papers (OCC), disperging must also improves fiber strength in addition to reducing unwanted contaminants. In bleaching systems, dispergers are used for intense mixing of the bleaching agents with the fibers.

Bleaching improves the optical characteristics of the stock. The brightness is increased with the penetration of chemical additives by bleaching the fibers and colour stripping as well as moving the colour spectrum.